Biological Phosphorus Removal

The basic principle of biological phosphorus removal is to expose bacteria to alternating anaerobic and aerobic conditions to promote “luxury uptake” of phosphorus. Under anoxic to anaerobic conditions, phosphorus accumulating organisms (PAO) have the ability to take in organic substrate. In order to obtain the energy to incorporate the organic substrate into the microbial cell under anaerobic conditions, the bacteria releases phosphorus into the wastewater. When aerobic conditions are restored, the organic substrate taken in is converted to energy and cell mass. This allows the bacteria to take in phosphorus then needed to fulfill its nutrient needs.

Advantages of Biological Phosphorus Removal

- Incorporates phosphorus into the sludge for ease of removal via WAS or Filtration

- Chemical addition savings

- Reduction of sludge production compared to chemical addition

Biological Phosphorus Removal

Activated Sludge

A well designed activated sludge process will include an anaerobic reactor, zone or period. The combination of this anaerobic selection and time based operation, leads to great phosphorus uptake, allowing for savings of chemical on processes with low phosphorus removal requirements.

Product Solutions

Aqua MixAir®

Aeration System

Learn More

AquaSBR®

Sequencing Batch Reactor

Learn More

AquaPASS®

Phased Activated Sludge System

Learn More

Aqua MSBR®

Modified Sequencing Batch Reactor

Learn More

Aqua CAM-D®

Combination Aerator/Mixer/Decanter

Learn More

OxyMix®

Pure Oxygen Mixer

Learn More

IntelliPro®

Process and Monitoring Control

Learn More

Featured Application

Optimizing biological phosphorus removal from an AquaSBR® System

The Middlebury Wastewater Treatment Plant located in Middlebury, Vermont treats domestic and industrial waste received from a local dairy and a brewery.

Read Success StoryVisit our Resources page for additional success stories and application profiles.

Biological Phosphorus Removal

Aerobic Granular Sludge

Based on the strategy of operation of the process for granulation with anaerobic feed and selective wasting, the aerobic granular sludge is an excellent system for enhanced biological phosphorus removal. It can achieve the lower phosphorus level biologically than activated sludge systems.

Product Solutions

Featured Application

AquaNereda® Aerobic Granular Sludge Technology

A plant with an average design flow of 2.11 MGD and a peak hour flow of 9.5 MGD. The plant is performing very well and easily stays within the discharge requirements of total nitrogen below 8 mg/l and total phosphorus of less than 0.5 mg/l in the winter. The energy consumption is 40% lower than similar size CAS systems in the area.

Read White PaperVisit our Resources page for additional success stories and application profiles.

Biological Phosphorus Removal

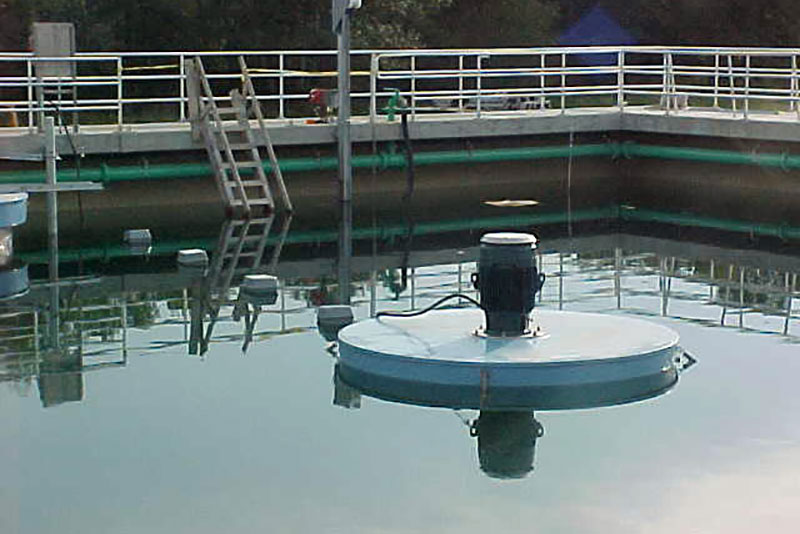

Anaerobic Mixing

Anaerobic mixing is needed for enhancing biological phosphorus removal. This could be achieved in separate tanks or zones. Completely mixing the system provides the ideal distribution of substrate and bacteria, driving the reactions more efficiently.

Product Solutions

Featured Application

AquaDDM® mixers chosen over submersible directional mixers for optimum anoxic mixing

To help meet the stringent water quality standards for denitrification, the facility has employed (20) 7.5 hp AquaDDM mixers. In 1994, Colorado Springs opted to install (20) AquaDDM mixers instead of installing submerged directional mixers.

Read Success StoryVisit our Resources page for additional success stories and application profiles.

Biological Phosphorus Removal

Membrane Systems

The combination of biological phosphorus removal and membranes is a great method of removing phosphorus. Biological phosphorus removal on the biological portion of the membrane system drives the phosphorus to the sludge, which is subsequently separated by the membranes.

Product Solutions

Featured Application

Oldest town in West Virginia adopts modern Aqua-Aerobic® MBR System to meet Chesapeake Bay initiatives

In 2010, Shepherdstown selected the Aqua-Aerobic® MBR Membrane Bioreactor as the new system which would treat the town’s wastewater. The decision was based on the ability to utilize the plant’s existing infrastructure without the need for additional tanks.

Read Success Story