Aqua-Jet®

Surface Mechanical Aerator

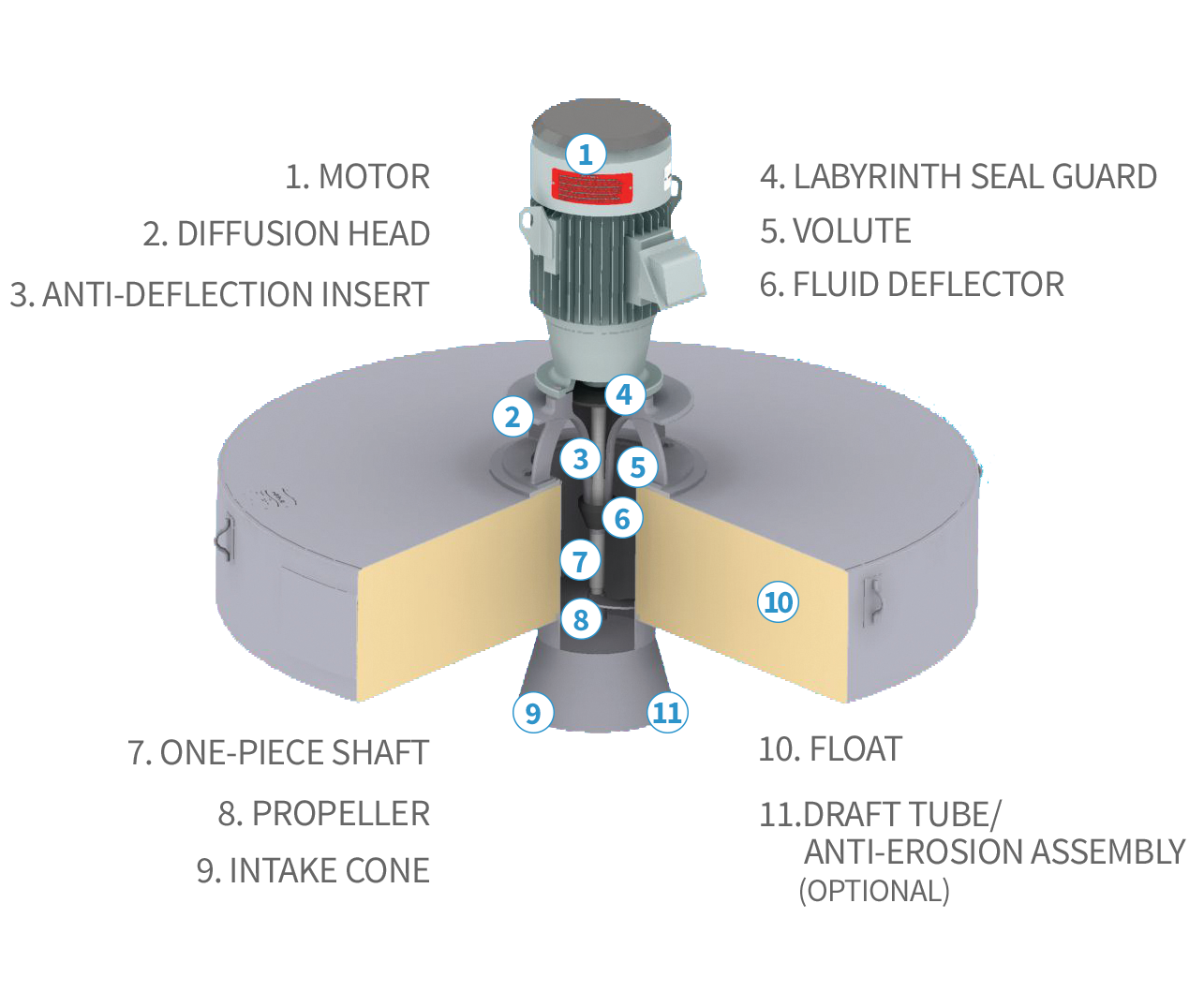

The Aqua-Jet aerator is a mechanical direct-drive unit designed to provide optimum oxygen transfer in a variety of municipal and industrial wastewater applications. The performance of the Aqua-Jet aerator also provides the mixing necessary to uniformly disperse oxygen and organic matter within the microbial population.

The robust design and use of the highest quality materials have also made the Aqua-Jet the most trusted aerator in the industry, outlasting other aerators 2 to 1.

How It Works

Basin water is pumped up into the intake cone and through the volute, and is dispersed through the diffusion head in a spray pattern.

Oxygenation occurs at two critical points:

- When the water exits the diffusion head, and

- When the spray enters the water surface

Features & Specifications

Motor

Standard 3-year warranty, severe duty, totally enclosed fan-cooled (TEFC), Class F insulation, 1.15 service factor

Diffusion Head

Monolithic casting, 304 stainless steel (ss), limits vibration

Motor Shaft

One-piece, 17-4 precipitation hardened (PH) ss, eliminates couplings

Float

Fiberglass or 304 ss exterior. Interior closed-cell polyurethane foam adds structural stability and prevents sinking. Heavy wall ss volute.

Propeller

Two-blade design precision cast, 316 ss, or 15-5 ss non-clog operation

Intake Cone/Anti-Vortex Cross

304 ss, provides minimum headloss

Benefits

- Vibration limiting design; velocity of 0.3 inches/second or less

- Proven oxygen and mixing performance

- Easy and flexible installation

- Short lead times

- Easily incorporated into existing plants

- Units are retrievable for easy access

- Various mooring arrangements available

- Endura® Series low maintenance motors save energy, reduce O&M costs and increase performance

Optional

SAF-T Float® Technology

The SAF-T Float® Safe Accessible Float Technology is the result of customer feedback for a solution that provides service personnel with safer, easier and more accessible maintenance on Aqua-Jet® aerators and AquaDDM® mixers. This new technology encompasses two critical features: 1) a docking station each float that receives a set of lightweight, removal handrails and; 2) a non-skid coated surface onto the section of the float where the handrails attach, providing a safe grip for maintenance staff to stand on the float.

How It Works

Features & Specifications

- Removal Handrail Design

- Light Weight

- Non-skid Surface on Float

- Locking Pin Design

- Indexing Slot for Positive Engagement

- Retrofit Existing Units for Handrail Installation

Advantages

- Safe Access to Aerators and Mixers

- Provides Maximum Worker Safety

- Multi-Faceted, OSHA Compatible Security

- Non-Compromising Performance

- Easy Installation in Less than Five Minutes

Plant Photos

Applications

Related Resources

| Resource Categories | Title | Summary | Download Link |

|---|---|---|---|

| Article | A New Platform For Safer Surface-Aerator Maintenance | A solution that provides service personnel with safer, easier and more accessible maintenance on Aqua-Jet® … | |

| Video | Aqua-Aerobic Systems, Inc. Overview Video | ||

| Brochure | Aqua-Jet® 50Hz Product Brochure | International | |

| Video | Aqua-Jet Aerator (no-audio) | ||

| Brochure | Aqua-Jet® Product Brochure | ||

| Brochure | Aqua-Jet® Product Brochure en Espanol | Folleto del producto en español | |

| Success Story | MaClaren Industries | MaClaren’s Pulp Mill Upgraded To Meet New Requirements And Aid In Protecting The Environment | |

| Brochure | SAF-T Float® Product Brochure |